Take a moment to consider the various types of plastics used in everyday life. From the plastic that is used in a water bottle to that which is used to create a prosthetic arm for a vet, there are many types of plastics, applications of it, and processes for producing it. Each component of plastic needs different features and elements, too. Some forms need to be more flexible and fluid than others. Some need to be incredibly strong to eliminate risk.

One of the key factors in producing plastics is the actual manufacturing process. There are numerous methods used and, with each one of them comes the need for different types of polymers to create that plastic. Take a look at a few key types of plastic manufacturing and when they are used.

3D Printing

One of the latest methods of manufacturing is the use of 3D technology. Called adaptive manufacturing, this method involves the use of layers and layers of polymers placed on top of each other to create a three-dimensional object. The process is faster, provides for more flexibility, and can be used in many applications. It also has a faster lead time and, depending on the application, can be used to create one highly specialized item or many. However, it tends to be best for low volume applications.

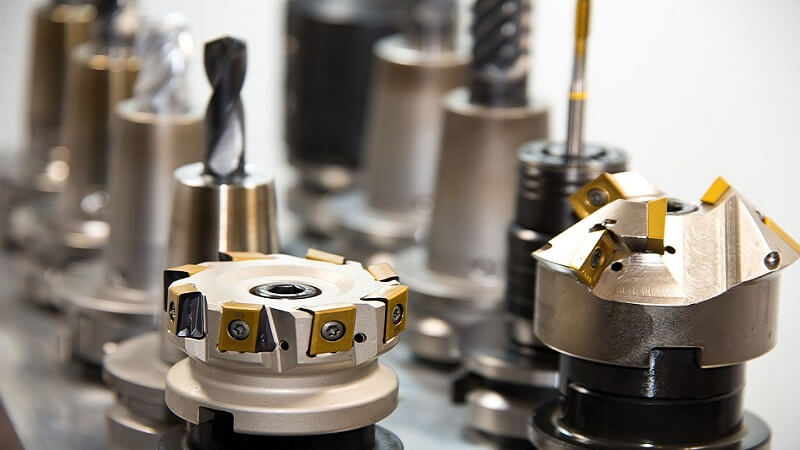

CNC Machining

A more commonly used method of manufacturing plastic is with the use of CNC machining. This is also commonly used with metal. Here, large blocks of solid plastic are used. The process uses a combination of grinding, drilling, cutting, shaving, and boring to create the designed end result. CNC machining is a type of subtractive process where the material is removed in some way to achieve the fixed result. Generally speaking, it is slightly more expensive than other methods but still has a short lead time. It can also handle low to high volume applications with ease. It is more expensive to handle per part, though.

Polymer Casting

A unique method for creating some types of plastic products is the use of polymer casting. In this method, reactive liquid resin is used to fill a mold. Sometimes, instead of resin, liquid rubber is used. When in place, the surfaces react chemically. They harden over time. This type of process is generally used for specific types of polymers including silicone, epoxy, polyurethane, and acrylic polymers. This method generally is best only for low volume applications but can be affordable to set up and to manage the cost per part. It has a short lead time and has a high degree of freedom.

Extrusion

This method of plastic manufacturing involves pushing the polymers through a die. As this happens, the soft and pliable polymers are able to take the shape of the die as a cross-section of the final component. This method offers a very low costing solution especially the cost per part. It is less complex to set up and does not require a high level of machining skill to make it possible. Generally, it works best for medium to high volume applications. This option, though, has a long lead time due to the creation of the die. That can make it inaccessible to some forms of plastic creation.

Rotational Molding

Rotational molding is an effective method of creating plastic products. In it, a hollow mold is heated and filled with a powdered thermoplastic material. From here, it is then rotated to cover the interior of the mold. This ends up creating two hollow objects within the mold. Also known as rotomolding, this method is not used often, but it can offer some benefits. It offers a good level of freedom in the form of the product, but only for larger and hollow components. It is a bit more expensive than some methods and works well for medium volume applications.

Blow Molding

More commonly used today than in the past, blow molding creates mostly hollow plastic components. To do this, a heated plastic tube is inflated within a mold. It grows to meet the size and dimensions of the mold itself. In this method, the desired shape is achieved, the polymer materials set, and the object is created. A common reason to use this method of plastic manufacturing is to create a specially shaped object, like a water bottle. This method is more expensive to set up but once in place, it is very inexpensive in terms of cost per part. It is also ideal for larger volume applications. There is limited freedom when it comes to the design and generally speaking, no complex geometric designs will work.

Injection Molding

Injection molding is a more commonly used form of producing plastic products. In this method, the polymer substance is injected into a mold (generally in the form of molten thermoplastic materials). The substance then takes on the shape of the mold and it hardens. Because of how this method is so versatile, it is also very commonly used to make multiple plastic parts for any type of project. It does have a long lead time, often several months in time. There is a moderate to a high level of form freedom, though. The cost per part is inexpensive, but the setup can be more expensive than other forms of molding. And, it works best, as a result, for high volume applications.

Overall, each of these methods of plastic manufacturing can offer a variety of benefits and features. Yet, companies must work to find a balance between the costs to set up and the costs to manage any project. When it comes to polymer manufacturing, it is essential to balance costs with timelines, but also with the flexibility, durability, and design freedom, each method can offer to find the right combination of features. As you take into the range of options available for any specific project, turn to Polymer Chemistry to learn more about how we can help enable new and improved methods of polymer manufacturing.

Entertales is on YouTube, Click here to subscribe for latest videos and updates.